Illuminating the Future: The Critical Need for Self-Cleaning Street Lamps

Dust buildup on street lamps is a global problem that reduces brightness, wastes energy, and increases maintenance costs—especially in polluted, coastal, and desert regions where light output can drop by over 50%. So, does a dust-resistant street lamp project exist? Yes. Advanced research and real-world deployments are already using self-cleaning street lighting technologies.

The Science of Self-Cleaning: Core Technologies Powering the Innovation

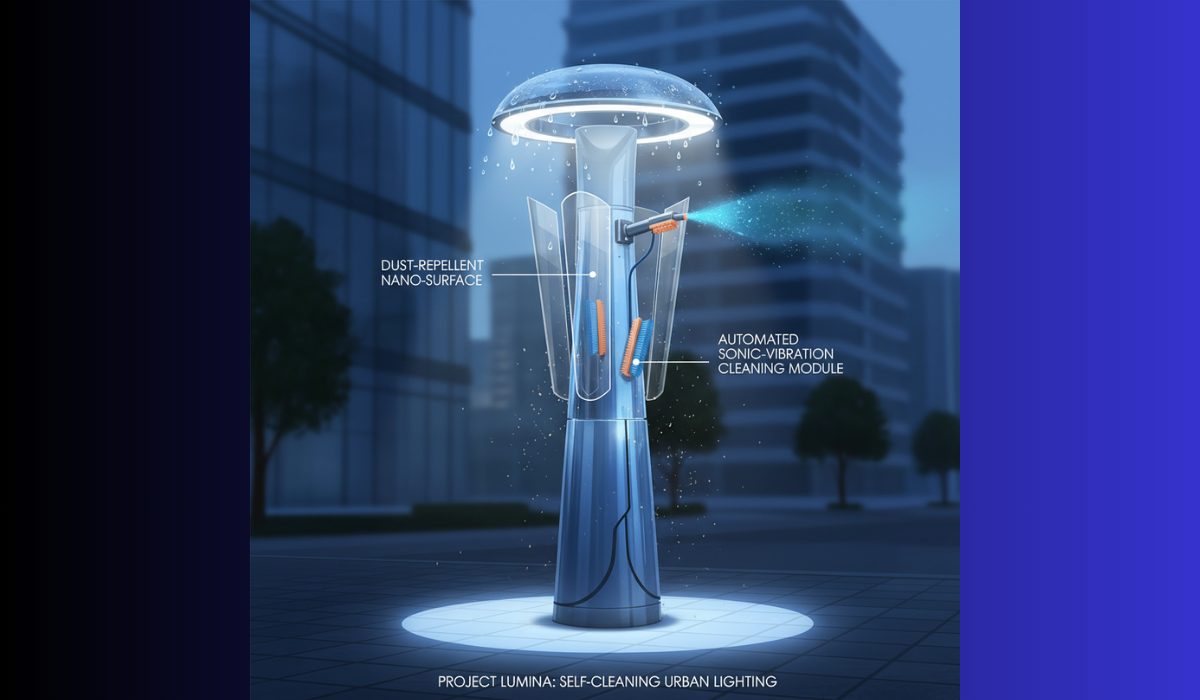

The research into self-cleaning street lamps is not based on a single idea but a convergence of material science and smart design. The goal is to prevent adhesion and promote the automatic removal of contaminants.

1. Superhydrophobic and Nano-Coatings (The Lotus Effect)

Inspired by the lotus leaf, this is the most prominent approach. A nano-scale textured coating is applied to the lamp surface, particularly the protective cover or “globe.”

- How it Works: The microscopic structure creates a high water contact angle, causing water droplets to bead up into near-perfect spheres. As they roll off, they pick up and carry away dust, dirt, and other particles.

- Research Focus: Studies, like those from the Daegu Gyeongbuk Institute of Science & Technology (DGIST), aim to enhance the durability and cost-effectiveness of these coatings for large-scale outdoor use. The challenge is ensuring the coating withstands long-term UV exposure and physical abrasion.

2. Photocatalytic Coatings (Titanium Dioxide – TiO₂)

This technology adds an active cleaning component. Coatings are infused with titanium dioxide nanoparticles.

- How it Works: When exposed to sunlight or the lamp’s own UV light, TiO₂ becomes photocatalytically active. It breaks down organic dirt (like bird droppings or pollution residue) at a molecular level. Subsequently, rain or moisture easily rinses away the decomposed material.

- Key Advantage: It doesn’t just wait for rain; it actively decomposes grime, making it effective in various climates.

3. Integrated Mechanical and Electrostatic Systems

Some research prototypes go beyond coatings:

- Electrostatic Dust Repulsion: Applying a low-power, periodic electrostatic charge to the lamp surface to repel charged dust particles.

- Integrated Micro-Cleaning Mechanisms: Designs incorporating tiny, automated wipers or air-jets activated by sensors that detect significant light output reduction.

Do Real-World Projects Exist? Examining Global Implementations

This is not merely lab-bound research. Pilot projects and commercial products are proving the concept’s viability.

| Project/Initiative Type | Region/Example | Key Technology & Reported Outcome |

|---|---|---|

| Municipal Pilot Projects | Middle East (e.g., UAE, Saudi Arabia) | Testing superhydrophobic-coated LED streetlights in desert environments. Outcome: Significant reduction in maintenance frequency and sustained lumen output compared to standard units. |

| Commercial Product Launches | Global (Specialized Manufacturers) | Companies now offer “low-maintenance” or “dust-resistant” solar and LED street lights featuring proprietary nano-coatings as a key selling point. |

| Academic & Government Research | South Korea (DGIST), European Union H2020 Projects | Developing next-gen durable nanocomposite coatings and standardized testing protocols for self-cleaning public infrastructure. |

Case in Point: The Desert Challenge

Cities in the Gulf Cooperation Council (GCC) states face extreme soiling rates. Traditional lamps require cleaning every 2-3 months. Pilots using coated lamps have extended this interval to 12-18 months, offering dramatic savings on labor, water, and operational costs while improving road safety through consistent illumination.

Measurable Benefits: Why Cities Are Investing in Research

The drive for these projects is fueled by clear, quantifiable advantages:

- Dramatic Reduction in Operational Expenditure (OPEX): Manual cleaning of street lamps is labor-intensive, risky, and costly. Self-cleaning technology slashes these recurring costs.

- Consistent Light Levels & Enhanced Public Safety: Maintains designed illumination levels, ensuring well-lit roads, parks, and pedestrian areas without periodic dimming.

- Improved Energy Efficiency: A clean lamp delivers more light per watt of electricity consumed. For solar-powered lamps, a clean panel is crucial for battery charging.

- Extended Lifespan of Assets: Reduced dirt accumulation mitigates overheating and potential corrosion, prolonging the fixture’s operational life.

- Sustainability Contribution: Reduces the carbon footprint associated with frequent maintenance vehicle trips and water usage for cleaning.

The Road Ahead: Challenges and Future Research Directions

While promising, the field must overcome hurdles for widespread adoption:

- Coating Longevity: The primary challenge is ensuring the self-cleaning efficacy lasts the 10-15 year lifespan of an LED street light.

- Cost-Benefit Analysis: The initial premium for coated lamps must be justified by long-term savings, which requires more publicized real-world data.

- Standardization: The industry lacks universal standards for testing and classifying the “self-cleaning” performance of outdoor lighting.

Future research is focusing on self-healing coatings that can repair minor scratches, multi-functional materials that combine hydrophobicity with anti-icing properties, and smart systems that integrate soil sensors with central management networks for predictive maintenance.

Conclusion: A Brighter, Cleaner Urban Future

Global research and real-world projects confirm that self-cleaning, dust-resistant street lamps do exist. By combining nanotechnology and smart design, these systems are set to become a standard feature in sustainable, smart cities, delivering brighter, safer, and more efficient urban lighting.